Drilled Threaded Assemblies Tapered & Straight

The most common type of well assembly style and size. Threaded well allows for insertion directly into process lines through pipe TEE’s or Laterals. They can also be inserted into tanks with half couplings or threaded outlets. They are available with a straight shank for longer wear and tapered to limit flow restrictions or when velocity considerations must be taken into account.

| Process Connection: | 3/4″NPT or 1″NPT |

|---|---|

| Well Material: | 304 & 316 Stn. Stl. Carbon Steel, Brass |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Drilled Threaded Assemblies Alloy Metals, Tapered

Other environments, corrosive conditions or when additional strength is required. Bar stock wells can be fabricated in a number of austenitic, ferritic or martensitic stainless steels, nickel alloys, chrome-molys or other specialty metals. Wrench flats are machined into the neck for installation since these alloys are usually only available in round stock. Wells are available with standard tapered, straight or step down shanks.

| Process Connection: | 3/4″NPT or 1″NPT |

|---|---|

| Well Material: | 310 & 446 Stn. Stl., Hastelloy C276, Monel 400, Inconel 600, F11, F22 |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Drilled Threaded Assemblies Stepped Down Shank

The stepped down shank construction provides a reduced wall thickness for the remaining 2 1/2″ of well length. This design allows for improved response time of the RTD element. Wells 2 1/2″ in length or less are supplied with the 1/2″ diameter step for the entire shank length.

| Process Connection: | 3/4″NPT or 1″NPT |

|---|---|

| Well Material: | 304 & 316 Stn. Stl. Carbon Steel, Brass |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Drilled Socket & Weld-in Bar Stock Well Assemblies

Socket and Weld-in bar stock wells are used in high temperature, high pressure service, most often steam. A regular product for the power industry where absolute leak proof permanent connections are mandatory. Socket wells are inserted into process lines through pipe TEE’s or Laterals or on to branch lines with socket outlets. Weld-in wells are welded directly into heavy wall tanks.

| Process Connection: | 3/4″NPS or 1″NPS, 1.315 or 1.5 Weld-in |

|---|---|

| Well Material: | 304 & 316 Stn. Stl. Carbon Steel, Carbon Steel, Chrome-moly |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Drilled Flanged Tapered, Straight, Stepped Down

Forged flanges in numerous sizes, ratings and facings mate to existing process flange connections in pipe lines or through welding neck flanges on reactors or tanks. These are available in raised face, flat face and ring joint connection. Flanges are welded to the bar stock stem on both sides. Optional full penetration welds are available for additional leak free protection.

| Process Connection: | Connects to Mating Flange |

|---|---|

| Well Material: | All grades of Stainless Steel, Nickel alloys, Hastelloy, Specialty metals |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Van Stone Well Assemblies Tapered, Straight

The Van Stone thermowell is machined from a single piece of bar stock with a neck the same as the face diameter of a 1″ or 1 1/2″ flange. This design allows for sandwiching of the van stone between the vessel process flange and a securing slip on flange. This design offers two advantages:

1. Any weld stress is eliminated.

2. The slip on flange not being exposed to the process conditions can be of a less expensive material.

| Process Connection: | Connects to 1″ or 1 1/2″ Mating Flange |

|---|---|

| Well Material: | All grades of Stainless Steel, Nickel alloys, Hastelloy, Specialty metals |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Pipe Well Assemblies Plain, Threaded, Flanged

A lower cost alternative to bar stock wells where pressure and velocities are low. Pipe wells are available in schedule 40, 80, 160 or XX strong, 1/4″ to 1″ pipe size. Plain wells can be welded directly into a tank or simply free hanging, threaded wells are supplied with a welded on NPT bushing for a threaded process connection, flanged pipe wells connect to a mating flange for a stronger connection. Pipe wells are commonly supplied in lengths up to 20 feet.

| Process Connection: | Welded, NPT Threaded or Flanged |

|---|---|

| Well Material: | All grades of Stainless Steel, Nickel alloys, Hastelloy, Specialty metals |

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Ceramocouples®

Ceramocouples® are a cost effective alternative where the process doesn’t require a thermowell or protection tube. Ceramocouples are available with the element sealed to a double ended fitting for a leak proof connection or spring loaded with the element captive to restrict side movement. Reducing bushings can be added for larger process openings.

| Process Connection: | 1/2″NPT Threaded |

|---|---|

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Oil Seal Thermocouples

Oil seal thermocouples provide an efficient method of measuring bearing temperatures. An “O” ring designed into the assembly prevents the lubricating oil from entering the connection head. Oil seals are available with a floating collar and S head block or O-ring sealing fitting.

| Process Connection: | 1/2″NPT Threaded |

|---|---|

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | 450°F (260°C) |

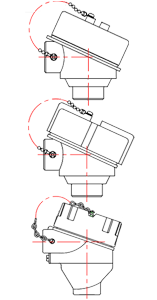

Remote Head Mounted Assemblies

A remote mounted head provides assurance that in the event of a well failure, the process media cannot leak into the head. A remote head is also useful where process vibration can cause connection problems within the head. It is an excellent method of utilizing a head where physical clearance at the process connection is limited. Remote head assemblies are supplied with a 1/2″NPT fitting for the well connection, the element terminates to PVC coated flexible armored leads of any length.

| Process Connection: | 1/2″NPT Threaded |

|---|---|

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Assemblies Less Thermowells Spare RTD Elements

Assemblies can be matched to fit existing wells or wells provided by another supplier. These assemblies can also be screwed into a bored opening of equipment housing. Replacement elements are available for any Thermo Electric assembly as startup or commission spares or manufactured and shipped to the site on express service.

| Process Connection: | 1/2″ or 3/4″NPT |

|---|---|

| Element Type: | Platinum, Copper, Nickel |

| TRC: | .00385, .003916, .003923, .00427(CU), .00672(NI) |

| Temperature Range: | -292 to +1202°F (-180 to 650°C) |

Connection Heads

The connection head performs two essential functions: It provides a method of terminating the RTD by means of terminal block or transmitter mounted inside the head. It also provides protection for the element from environment and mechanical conditions. Thermo Electric’s large device connection head is capable of containing excess coiled lead wire or a number of the large smart transmitters.

| Material: | Aluminum, Stainless Steel, Cast Iron or polypropylene |

|---|---|

| Terminal Block: | 4 Point and 6 Point Standard, Transmitter |

| Certifications: | NEMA-4, 4X, Explosion Proof FM, CSA, ATEX |